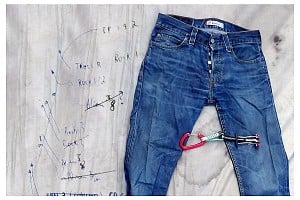

Just had some expansion bolts delivered this morning, they were advertised and labelled as FIXE Stainless Steel. To my eye they don't have the same stainless steel sheen that I'm familiar with from other manufacturers.

The expansion bolts are marked:

M12 x 110

F

The nut is marked |8| s

No marks on the washer

Can anyone confirm that they are are stainless steel or not?

The numbers are usually the tensile strength i think, where did you get them from ?

Alpinetrek

Are they magnetic?

Been searching for a magnet but can't find one!

Most current bolts have the grade marked on the side, A2 equivalent to 304 and A4 is 316, iirc a plated steel would be 8:8. It'll be easier in the future, as the requirements of the latest version of EN959 state that the material or class of the bolt should be clearly marked and visible when placed, so the obvious place for an expansion bolt would be on the striking surface.

+1

A good call as I'd assume that the SS used for bolts isn't magnetic. Basic SS is ferritic and is therefore magnetic. But most common SSs are austenitic and so not magnetic due to added nickel and chromium content. When brand new, I've found that sometimes SS and galvanised maillons are pretty hard to tell apart, so my fallback position is to then reach for a magnet.

To the OP: Not all SS finishes are the same but I understand what you mean by the 'sheen'. But, unless I'm totally mistaken, I've always assumed that the metal used in manufacture isn't actually recorded on bolts as this isn't required by law.

Ah, yes I do

> Are they magnetic?

According to my fridge magnet these bolts are indeed magnetic.

I checked a stainless bolt and hanger which are not magnetic.

Does this test with a magnet 100% confirm that they are not stainless, or could they just be a lower grade of stainless steel?

From experience non stainless bolts corrode very quickly in the slate quarries I'm guessing it would be best not to use these until someone can confirm that they are ok.

> Alpinetrek

Maybe post the link to the specific bolts you ordered? You could also maybe query alpinetrek directly - I found them fairly helpful when I needed info on some of their glue-ins I bought once.

They’re not SS.

My advice would be to send them back to the retailer, get a refund, and then spend the money on Petzl or Bolt Products kit.

A2 and A4 stainless is non-magnetic until you work (bend) it and it becomes slightly magnetic, rolled thread wedge bolts are very slightly magnetic but you need a powerful magnet to detect it.

However Fixe also make bolts from a grade of Duplex stainless steel (we don´t know which grade) under the trade name of PLX and this IS magnetic.

I'm in the middle of an email exchange with them....

> However Fixe also make bolts from a grade of Duplex stainless steel (we don´t know which grade) under the trade name of PLX and this IS magnetic.

Would they be resistant to corrosion?

PS The best bolts I've ever used were the ones you donated for by big multi pitch routes in Twll Mawr

> Most current bolts have the grade marked on the side, A2 equivalent to 304 and A4 is 316, iirc a plated steel would be 8:8. It'll be easier in the future, as the requirements of the latest version of EN959 state that the material or class of the bolt should be clearly marked and visible when placed, so the obvious place for an expansion bolt would be on the striking surface.

We shall see how the proposals pan out and what the manufacturers do, the amount of information we are supposed to mark on the bolt you´ll need an electron microscope to read it especially as it will have to be on a surface designed to be hit by a hammer!

Luckily the marking requirements have always been interpreted liberally by the manufacturers (read that as ignored) as there are exemption rules regarding marking products for CE/EN, you can put the information elsewhere if it is impractical to put them on the product, it´s unsightly, damages the product etc.

> Would they be resistant to corrosion?

> PS The best bolts I've ever used were the ones you donated for by big multi pitch routes in Twll Mawr

Well they should be but the ones they recently recalled weren´t!

The ones you donated were the twisted glue ins which needed a 16 / 17 mm hole, perfect for slate.

I think a simple 1,2 or 3 for the class would do it as that's all you really need to know.

Yep, duplex means a mix of austenitic and ferritic so I'd expect PLX to be magnetic. I've just ordered some PLX product to test and find out what it actually is.

Greg Barnes at the ASCA had some analysed and someone else as well with two different results! Fixe actually said it´s 1.4462 at some stage though. The standard should require the manufacturer states the material, rather than hiding behind a trade name, currently Fixe can chop and change the material at whim with no comeback if the customer experiences problems, as is the case with them simply saying "stainless steel" with their previous products.

The marking proposals are bonkers, just putting a "1" or "2" would be no problem but the current proposals require the manufacturers name, the material, the model, the batch number and probably something I´ve forgotten, all this in a 6mm dia circle which is intended to be hit repeatedly with a hammer and still legible when installed.

It´s all to do with the UIAA pushing responsiblity onto the manufacturers and is a typical "shutting the stable door after the horse has bolted" approach. There is no system in place to record any of the information we put on the bolt, no requirement whatsoever that we store the information and the current data protection laws make it unlikely we would be allowed to release customer-specific data of that kind anyway, that is, if the UIAA or any one else asks did I provide a particular bolt to a customer I´m not allowed to tell them.

The obvious solution to traceability on the cliff (to find out what works and what doesn´t) is to set up a central database where developers can record what and when they fitted fixed anchors but this is too pro-active for the UIAA (that is it would involve them actually doing some work and spending money) so was dismissed out of hand.

Would you be able to let me know what happens with Alpinetrek, as I've purchased bolts from them in the past under the impression they were stainless steel.

Problems might arise returning said bolts as they've already been placed.

They asked me to send photos and after seeing them they admitted that they were not stainless steel even though they were advertised and labelled as such. They said they would refund me and that they didn't want the bolts mailed back as this would incur costs. The bolts are obviously useless for outdoor use in the UK.

That sounds like some seriously dodgy practice to me. It's effectively selling not-fit-for-purpose PPE. I would hope they would have a pretty good explanation as to how this could have happened and the steps they are now taking to ensure it can never happen again.

Agree.

I also worry about the non stainless bolts and hangers advertised on line and on eBay, who buys these and what do they do with them, very worrying...

As long as they were up to strength they would be fine in many places here in Ariège, as I've bolted quite a few lines now that pretty much never get wet in any weather. But I can't think of many UK routes you could say that about.

Indoor climbing walls, and also some non-climbing rope access applications use them.

Only austenitic (the material grain structure) grades of stainless steel are non magnetic so given rock climbing anchors are either made from austenitic stainless (304, 316, 316L, 904L and 926) that leaves Duplex grades that are magnetic. By default that would suggest the fixings you have are Duplex.

Greg Barnes had a sample of Fixe PLX hardware tested in the US and it was confirmed as Duplex 2304. That said, the DAV also tested a PLX chain assembly and Stationary Spark Emission Spectrometer (OES) testing determined a range of material grades used throughout the product (Austenitic 304, Duplex 2205 and 2304) despite it all being labelled PLX. This is less of an issue for an expansion bolt and hanger so I would 'bet' that the bolt and hanger are all Duplex (presumably 2304).

There again as an aside you may find the clip to be 316 : )

Have a look on the clip...

304 Stainless used to be the default standard material however the trend is more towards 316 as a minimum grade (as evidenced by product ranges) with Duplex grades 'ranked' above so broadly speaking Duplex should offer an enhanced level of resistance to corrosion in UK areas given the general corrosivity levels throughout UK crag environments.

It's not just the material for the applicable environment (suitable corrosion resistance) but additionally where it has come from (quality) and the consistency of the material and fabrication process.

The QA and QC that a bolt manufacturer has in place to ensure consistency and reliability of their products is very important. Something for example that both Jim (Bolt Products) and Martin (Titan Climbing) do very well.

I'm talking about the revised EN959 standard, which has nothing to do with the UIAA whatsoever, other than some people who are on the CEN working group are also UIAA SafeCom members. The marking protocols are in line with other equipment, so although a bit of a pain I can see why they are as they are. Not too difficult to do on a standard hanger so will be interesting to see if that is where expansion bolt manufacturers decide to mark - I don't see anything in the standard which would prevent this. For resin anchors, well I've seen some manufacturers have already started marking batch numbers and manufacturers logos so it is doable, just at the cost of a laser engraver and another manufacturing step. I don't think a central database would ever work, climbing is not a regulated activity in that way, certainly not in the UK.

> That sounds like some seriously dodgy practice to me. It's effectively selling not-fit-for-purpose PPE. I would hope they would have a pretty good explanation as to how this could have happened and the steps they are now taking to ensure it can never happen again.

Could this be a case for your local trading standards?

I'm disappointed with Alpinetrek, still no refund but my main concern is that they are still listing the Fixe Stainless Steel M12 Bolts at 60p.

There are other technical inaccuracies on their website. Such as Coeur 'HCR' wedge bolts specified as 904SS when they are 926SS.

The Petzl 'HCR' hanger is 904L.

> I'm talking about the revised EN959 standard, which has nothing to do with the UIAA whatsoever, other than some people who are on the CEN working group are also UIAA SafeCom members. The marking protocols are in line with other equipment, so although a bit of a pain I can see why they are as they are. Not too difficult to do on a standard hanger so will be interesting to see if that is where expansion bolt manufacturers decide to mark - I don't see anything in the standard which would prevent this. For resin anchors, well I've seen some manufacturers have already started marking batch numbers and manufacturers logos so it is doable, just at the cost of a laser engraver and another manufacturing step. I don't think a central database would ever work, climbing is not a regulated activity in that way, certainly not in the UK.

I´m talking about EN959 as well, the UIAA stuff is of no interest. However the draft for eN959 includes enormous amounts of UIAA derived stuff which has no business being there, the appendix being the main example. The manufacturers have nothing to do with the ph vlue of the rock and all the rest, that is to do with the installer. Since EN959 is purely a manufacturing standard then all we need are the performance requirements, nothing else.

The proposed marking protocols are in line with a different set of standards and requirements (in fact they vastly exceed the requirements for nearly all other equipment) not the one governing bolts and there is no good reason to bring them in line. Marking bolts doesn´t make them any better.

The bolt IS the anchor, they are certified seperately from the hanger and sold seperately so will have to be marked seperately.

Have you seen the cost of a CNC Fibre laser engraver? And the fixtures we will have to make to hold the items?

Talking to other developers we guess that about half of the 5m bolts currently installed could relatively easily be identified and logged onto a database with the resin used, approximate date of installation and so on which would give us something to work on when failures occur, if we don´t try then we are back to blindly guessing.

Do Petzl state anywhere that the bolt is 926? On the Petzl website I can only see the bolt listed as part of the full assembly and the description implies all parts of the assembly are 904.

The hanger is stamped 904L, which is a low carbon version of 904 stainless steel and can be seen by zooming in on the image at: https://www.petzl.com/US/en/Sport/Anchors/COEUR-HCR

Regarding the wedge bolt, download the Technical Notice and read Section 4 under markings and you will find the wedge bolt is marked 1.4529 or in AISI speak: 926 grade SS.

Historically Petzl produced just 304 and 316 grade mechanical expansion anchors as this resisted much of the corrosivity encountered by developers installing those grades of products. This changed when a French Guide in the Caribbean fell onto a hanger that failed and he tried unsuccessfully to sue Petzl.

304, 316 and recently 926 grade bolts effectively reflect a product range to match corrosion conditions from NO Stress Corrosion Cracking (SCC) to SCC. Here the percentage of molybdenum (moly') is integral to preventing SCC and while 904L was resistant to SCC as compared to 316 during salt evaporative testing conducted by the UIAA, trying to get hold of 926 plate from which to make hangers was apparently difficult at the time this specific product was developed. 926 grade steel expansion bolts are readily available from Hilti and Fischer as they have industrial applications and contain the 6% minimum moly' content in line with oil industry standards where the cutoff to regard any steel as 'HCR' is 6% moly'. The hanger can be fabricated from a lower grade material since it is external to the rock, therefore readily inspected visually and can easily be replaced. Based on PREn however 904L is considered 'HCR' but based on moly' content it is not and the latter is certainly more important from what has been learnt regarding SCC so far. Ultimately the term 'HCR' is ambiguous. Steel grade is meaningful in describing the material but says nothing really about resistance to corrosion yet 'HCR' says nothing about composition but makes generalisations about corrosion. The key point is in matching material properties to resist the level of corrosion in the specific environment in which it will be installed e.g. 304 maybe fine for one environment but won't last a year in other areas. Generic statements such as use 316 in coastal areas because it is 'marine grade' help in some ways (by discouraging e.g. 304) however don't actually address the overall problem of managing corrosion.

The prEN actually says use 316 everywhere outside unless SCC is expected or has been discovered. What is and isn't considered suitable for SCC (class 1) is more contentious, I agree. My main criticism of the standard, which I fed into the review, was that as you suggest, it concentrated too heavily on materials - what about design, such as passivating surfaces, stress relief and so on? Our advice is to use only glue-ins on sea cliffs/coastal locations, ideally weld-free on the outside of the bolt. 25 years of service and inspection of 316 DMM ecobolts at UPT suggest that for UK conditions this is a suitable guideline. Whilst no SCC has been reported on UK crags, we've got a couple of test beds which will hopefully enable us to pick up any problems, but as you say, it is so conditions dependent that we may only ever know when or if a bolt fails.

Surely you are entitled to a refund as they are "not of merchandisable quality". Trading standards are the body to go to as it appears that alpintrek are potentially selling safety equipment which if installed in the wrong location prematurely fail resulting in serious injury or worse.

There is a more general public protection issue here isn't there.

I've returned stuff to alpinetrek before and never had any issues, they've always refunded me promptly. Do bear in mind that they are in Germany, so it might take longer for the refund to clear banks etc.

They are not based in the UK so as far as I'm aware so going down the Trading Standards may be more complex I guess.

I did receive a refund this morning and as I've said previously they don't want the 15 x 'plated steel' M12 bolts returned. They will be of little to no use to me unless I can sell them to someone for indoor use. I didn't jump at Alpinetreks offer of keeping the bolts and a refund I would rather have 15 x Stainless Bolts as ordered.

As with most climbers who buy bolts and hangers, it's not really for their own benefit, but for the collective good of the climbing community, a kind donation to the cause would not have gone amiss

Ah!

That's a pain. UK Trading Standards, as with other enforcement authorities only have jurisdiction in their own territory. I've no idea whether the UK trading standards would act on a complaint from a non UK country or whether there are equivalent organisations whrer alpintrek are based.

PS - you could try this lot: https://www.ukecc.net/contact-us/