Beal is a small family entreprise, situated in Vienne, in the French Department of Isere.

Despite its modest size, Beal qualifies as the world's premier manufacturer of climbing and security ropes.

This leading position is explained by indisputable technical advances in the production process compared to its competitors.

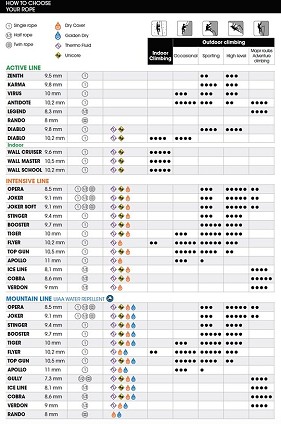

With a wide range of rope choice there is a rope available to meet your needs. To assist helping you choose your next rope Beal have put together a table listing all their climbing rope. The rope is catergorised into one or more of the following three lines, depending on its finish: ACTIVE LINE, INTENSIVE LINE & MOUNTAIN LINE.

ACTIVE LINE

Our ACTIVE ropes have been designed to cover the largest range of climbing disciplines possible, from the occasional outing to big walling with sport and indoor climbing in between. They are all constructed using BEAL's advanced technology which provides excellent impact absorption thanks to low impact forces.

The INTENSIVE ropes are designed for hard work in the mountains. Every individual sheath strand has been DRY COVER treated to provide astonishing results: an increase in durability, moisture resistance and suppleness whilst reducing overall weight. All ropes are manufactured using THERMO FLUID process creating a more compact and supple rope.

Specifically developed for climbing in challenging weather conditions found when mountaineering or ice climbing, MOUNTAIN ropes benefit from two treatments: in addition to the sheath's DRY COVER treatment, all core strands are individually treated with water repellent coating. The combination of both treatments creates a GOLDEN DRY rope. All MOUNTAIN ropes are GOLDEN DRY. They therefore feature the same benefits as INTENSIVE ropes, but with minimal water absorption and increased suppleness. All MOUNTAIN ropes are UIAA WATER REPELLENT accredited, and are constructed using the THERMO FLUID process creating a more compact and supple rope.

Within the table some rope options will come with UNICORE PROCESS and/or THERMO FLUID process.

An astonishing process, bonding rope sheath and core without affecting the rope's suppleness. If the sheath is cut or torn, the core and sheath will remain bonded together. With a standard rope, if the sheath is cut by abrasion over an edge, a frequent occurrence in mountains, it slides and gathers over some metres. It then becomes impossible to pass this zone, whether ascending or descending.

An infrared treatment which stabilises the sheath fibres and therefore makes yarns more homogeneous. The result is a more compact, better handling rope.

Comments